What AIM Does Best

At the Advanced Institute for Manufacturing, or AIM, we help small and medium sized manufacturers throughout the Mohawk Valley. We do this by providing them with the training, consulting, and technology services they need that will lead to new product development, cost reductions, increased efficiency, and profits.

Why Work with AIM?

AIM has the credentials you can count on, and the experts you can trust. We are designated by NYSTAR and NIST as a Manufacturing Extension Partnership (MEP) center. MEP has 588 field locations throughout the United States and more than 1,200 technical field staff. We provide comprehensive programs and services to manufacturers in a variety of industries.

Our Client Impact

Who We Serve

At AIM, we take great pride in helping small to medium sized manufacturing companies throughout the Mohawk Valley meet their goals. We’re pleased to provide a number of services, including consultation and training, that can help them grow their business.

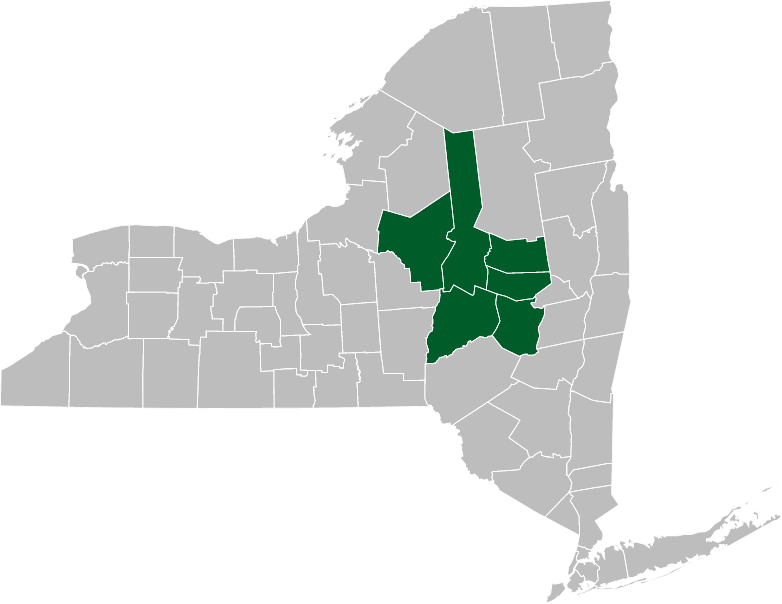

MVCC Advanced Institute for Manufacturing (AIM)

Providing services to manufacturers in Oneida, Herkimer, Fulton, Montgomery, Otsego, and Schoharie counties

Featured Case Study

Taylor Made by Lippert

CTM Corp. is a high-precision machine shop that can design and manufacture products from prototype to production. CTM Corp. provides top-quality work and services to the Aerospace, DoD, Medical, and Firearms Industries. They are located in Frankfort, NY and employ 19 highly-skilled employees.

Challenge

Taylor Made by Lippert is a trusted American manufacturer of customized marine components and premium boating accessories. They specialize in aluminum welding and frame fabrication for boats and trains, combining expert craftsmanship with innovative engineering. Located in Gloversville, NY.

Solution

Like many manufacturers, Taylor Made by Lippert, faced a challenge: it couldn’t rely on walk-in hires with no prior training to fill skilled roles. With approximately 35 veteran employees nearing retirement and growing demand for their services, Taylor Made by Lippert needed a long-term workforce strategy to develop new talent while upskilling its current team.

At the same time, Taylor Made by Lippert recognized the opportunity to extend its workforce development strategy to include both current full-time Team Members and Lippert Scholars High School students.

Results

To address these needs, Taylor Made by Lippert partnered with the New York State Apprenticeship Program, MVCC instructors, AIM industry experts, and Modern Welding to design a multi-path training initiative:

- Lippert Scholars High School apprenticeships: Recruiting 18+ students from BOCES as part of the Lippert Scholars program to begin welding apprenticeships, leading to journeyman-level certification from the NYS Department of Labor.

- Employee upskilling: Full-time Team Members participate in an 80-hour training program, delivered in weekly four-hour sessions. The curriculum covers MIG and TIG welding, with a strong focus on developing aluminum welding skills that meet the stringent standards of the transportation industry.

- Pre-apprenticeship programs: Shorter training opportunities serve as a screening process before more in-depth training.

- Funding support: Costs are offset through grants and tax incentives, including the SUNY Workforce Training Program, which provides resources for non-apprenticeship training in areas like Lean and Six Sigma.

“At Lippert, we see training as more than just a skills program — it’s an investment in people”

“At Lippert, we see training as more than just a skills program — it’s an investment in people. Our commitment is to create opportunities not only for current Team Members to advance their careers, but also for the next generation through our High School Lippert Scholars program. By building these pathways, we’re ensuring that highly skilled talent is ready to step into critical roles and help carry our company, and our industry, into the future.”